SG Blog

-

Insights & Innovations in Sustainable Composting

Explore expert perspectives, project highlights, and the latest advancements in composting technology and environmental sustainability.

Making Waves, the Membrane Covered ASP Composting Tsunami

ASP composting relies on forced aeration to maintain aerobic conditions and optimize biological activity. There are two primary methods: negative aeration and positive aeration with temperature feedback.

INTERVIEW WITH A BIOSOLIDS EXPERT

Biosolids expert Dan Collins, P.E., shares insights on safe, efficient composting.

Summary of Performance GORE® Cover and Negative ASP

GORE® Cover was evaluated to quantify the performance versus an existing negatively aerated static pile.

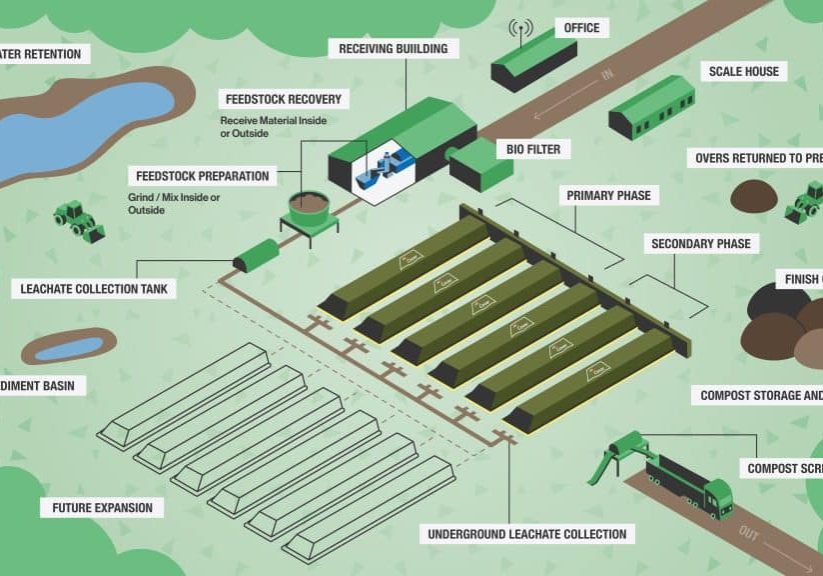

Composting Facility Delivers Significant Environmental Protection

The East Coast’s largest food waste composting site processes 57,000 tons of organics annually.

Exceeding Air Quality VOC Emission Regulatory Compliance in California

SG systems consistently meet and exceed California air quality regulations.

Positive ASP Composting: the Future of Organics

Two of the biggest issues faced by commercial composting operators are emissions (odor and VOCs) and moisture management.

Proven Results: Over 20 Years Reducing Odors and Emissions in California

Sustainable Generation, LLC and the GORE® Cover have a long track record of success.

Why Smart Composting Facility Operators Keep Stormwater and Leachate Separate

During heavy storms, composting facilities face increased runoff and leachate.

Press & Industry News

Latest Coverage Featuring Sustainable Generation®

Innovations in Composting Technology: Reducing Footprint and Increasing Efficiency

Scott Woods, CEO of Sustainable Generation®, discusses how the SG GORE® Cover technology is utilized in the most significant food waste composting operation on the East Coast, highlighting advancements in composting efficiency.

Sustainable Generation's Success in Organics Recycling

An overview of Sustainable Generation's achievements in renewable energy and organics recycling, focusing on innovative composting solutions.

Cutting Edge Organic Waste Processing with Sustainable Generation®

Brian Fuchs, Global Business Specialist at GORE® Cover System, discusses how CSWM's creative composting project sets a new benchmark for organic waste processing.

Sustainable Generation's Advanced Composting Technology to Revolutionize Food Waste Management for New York City

This is an in-depth look at how Sustainable Generation's SG Bunker® System with GORE® Covers transforms the Staten Island Compost Facility into a state-of-the-art operation, setting new standards in environmentally responsible food waste processing.

Sustainable Generation CEO Talks Solar-Powered Composting and Infrastructure Trends

Scott Woods highlights a new facility built at a Republic Services landfill, emphasizing trends around PFAS and community relations in composting infrastructure.